Take your production to the next level

with Powerful Features

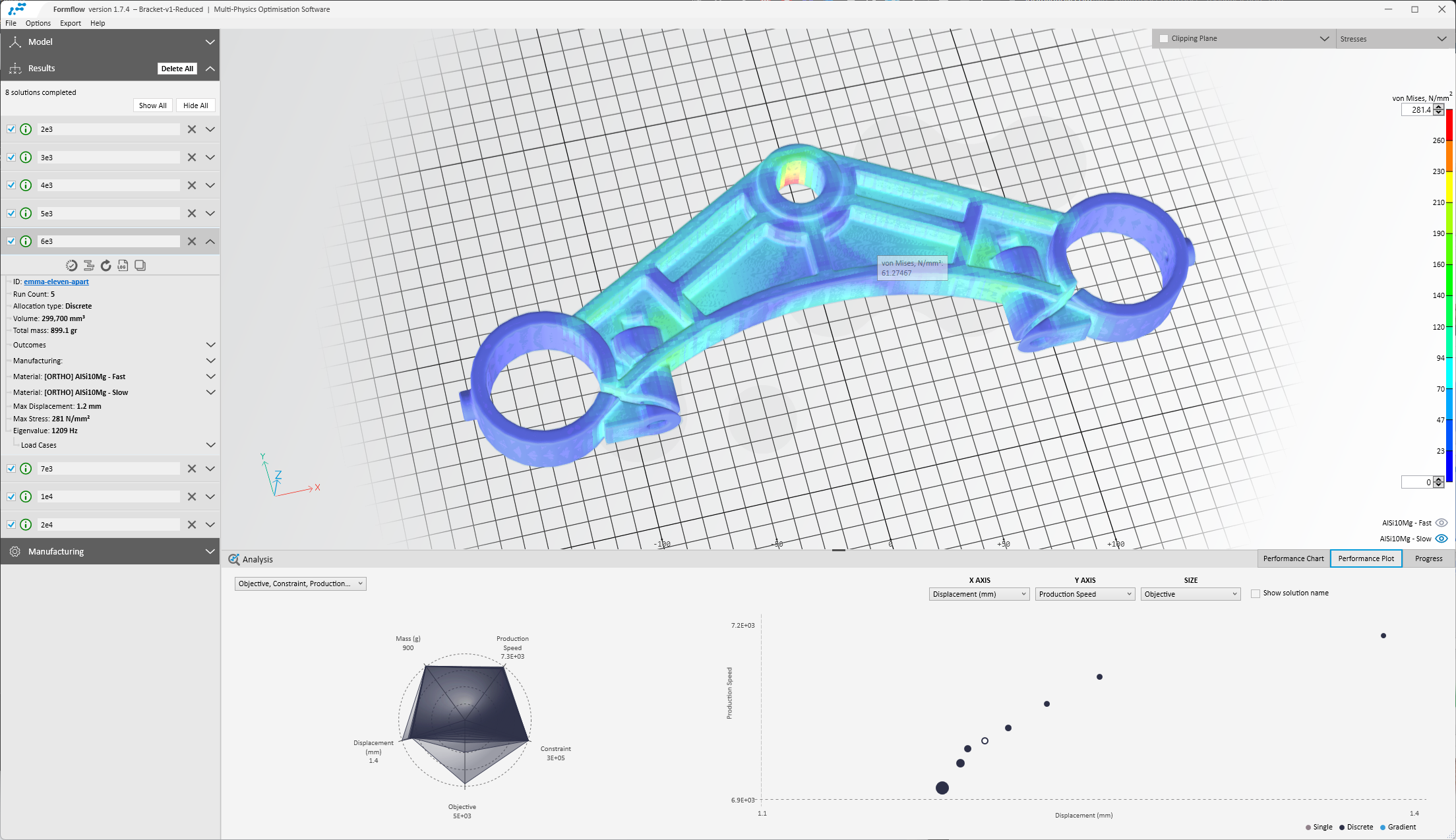

Multi-Objective Optimisation

Every engineering and production process has competing requirements; Cost vs. Quality, Reliability vs. Speed, Innovation vs. Assurance.

With Formflow it is possible to optimise fixed geometry component by specifying exactly the requirements you are looking for on local regions of engineering parts, while optimising for specific business needs like cost and sustainability.

Multi-Physics Simulation

Our proprietary algorithms optimise multi-functional parts (i.e. thermal, frequency) by integrating multiple physics within a coupled optimisation loop. This allows allocation of material properties that address the specific local needs of a part.

Close the data loop by integrating test and quality assurance with data models to iterate and improve through product development lifecycles.

Take the guess work out of optimising you production

A proven and robust production optimisation workflow.

Maximise your machine productivity whilst meeting your engineering requirements in a simple and holistc workflow.

- Reduce your cost of production by 36%

- Up to 200% faster production

- Increase your sustainability by 21%

A powerful workflow

Connect and scale your repeatable workflow.

- Accelerate your development time with simulation 2,000x faster than competitors

- Build prep from 80 hours to 10 minutes

- A workflow that is 480x more efficient

Validated Quality Optimisation

Achieve material and part certification with full confidence

- Reduce time to certification from month to days

- Zero non-conformance and 30% cost savings

- 87% reduction in process-induced residual stress